22

2022

-

02

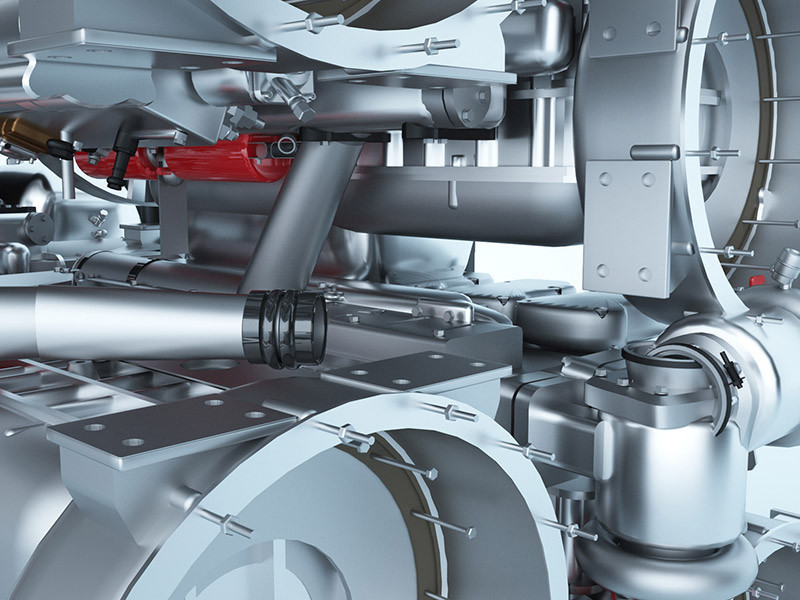

What are the ways to reduce noise in screw air compressors?

When the machine is in action, it will definitely make a sound. Some of the sounds are louder and some are relatively small. Therefore, we still need to pay attention to several aspects when using it. Here we also reduce some of its noise. The method has introduced the content to everyone, and you can take a look if you want to know more.

What are the ways to reduce noise in screw air compressors?

1. Vibration reduction. Installing external damping surfaces constructed of resilient materials on structures is an effective way to reduce machine vibration (and sound). The larger the damping barrier, the more effective its means of reducing vibration. This may prove to be a cost-effective solution.

two,

Soundproofing. This involves placing a sound barrier between the sound source and receiver. This means that only part of the sound can be isolated, depending on the barriers and their respective properties. Larger, heavier barriers are clearly more effective than smaller barriers.

3. Sound absorption. By installing a porous absorber (attached to the barrier) around the sound source, the noise reduction level is increased over that provided by insulation alone; consider open-cell polyurethane foam or heavier cloth applications.

4. Vibration isolation. By preventing vibrations from passing from one part of the structure to another, you can also reduce sound levels through correlation. A common area of vibration transfer is the passage of large machinery through the floor. Steel springs, cork, plastic and rubber are all effective ways to reduce this transfer and any associated noise. The choice of material depends on the size and surrounding space of the machine, as well as the stability requirements of the machine.

Keywords:

air compressors

Related News